Geordi Stainless

131 Herald St Cheltenham 3192 Victoria

Web: www.geordi.com.au Email: sales@geordi.com.au

Ph: 03 9553 2000 Fax: 03 955 33 888

Back to Products List

Back to Products List

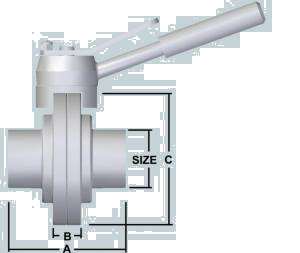

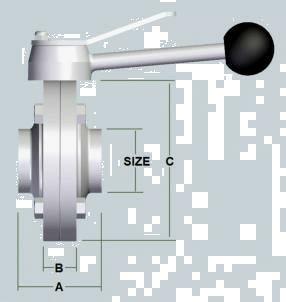

Butterfly Valve Information:

Details for Sudmo Butterfly Valve

BUTTERFLY VALVE SEAL INFO

|

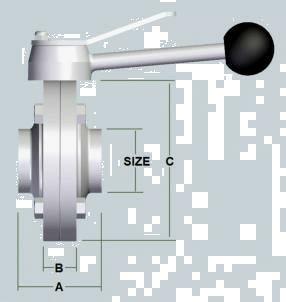

SIZE

|

A

|

B

|

C

|

|

25mm

38mm

50mm

63mm

76mm

100mm

150mm

|

50

50

50

50

84

|

20

20

20

20

|

84

96

109

126

141

161

230

|

|

Working Pressure: 10Bar

Vacuum: Min 4000Pa

Wetted Surfaces: Ra 0.8um.

Valve material: AISI 316

Seal Material options: Silicone(std), EPDM, Viton, Teflon, Nitrile & Hypalone.

|

Straight Forward engineering - High quality seal clamped body halves. The aerodynamic

design of the disc produces an extremely low resistance to flow - this also ensures

perfect cleaning by simple flushing (cleaning in place). The smooth flow through

the valve prevents deposits due to product residue. Each manually operated butterfly

valve can be fitted with pneumatic actuator with various spring/air configurations.

A variety of high quality seal material options catering for a large range of chemical

and temperature environments.

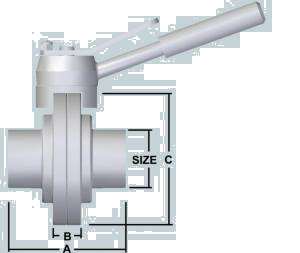

Details for Geordi Butterfly Valve

|

SIZE

|

A

|

B

|

C

|

|

25mm

38mm

50mm

63mm

76mm

100mm

150mm

|

66

76

80

80

82

90

80

|

18

18

18

18

18

18

36

|

79

85

105

112

125

157

212

|

Geordi Butterfly Valves are obtained from hot forged & heat treated pieces in AISI

304/L or 316/L material. They are assembled together with a hollow screw head, alternated

to allow the ability to interchange with various standardizations. Sizes range from

1"(25mm) to 6"(152mm). They resist to 15Bar working pressure and come complete with

an AISI 316 grade pressed seal plug worked on all the surface and grinded on rotating

parts and are supplied with 2 anti seizing Telfon sleeves. The standard seal is made

from silicone elastomer, however different materials are available upon request.

These valves can be supplied with manual configurations or pneumatic actuators in

accordance with your requirements. Standard finish is polished outside and satin

inside.

Silicone Rubber (Vinyl Methyl Polysiloxane): complying with food industry hygiene

requirements & compatible with most beverages, foods and cleaning solutions.

EPDM (Ethylene Propylene Diene Monomer Rubber): in accordance with food industry

hygiene requirements & particularly compatible with hot water, steam and cleaning

solutions.

Nitrile Rubber (Acryl Nitrile Butadine Rubber), in accordance with food industry

hygiene requirements & extra compatible with aliphatic hydrocarbons, vegetable and

animal oils with a working temperature up to 100°C.

Viton (Fluor Rubber): Extra compatible with many of the more aggressive chemicals

and higher working temperature than Nitrile.

Hypolone (Chlorosulfunated Polyethylene): Particularly suitable for organic and inorganic

acids and bases.

PTFE - coated EPDM-seals: For aggressive products with PTFE (Teflon, Hostaflon) is

compatible only.

Back to Products List

Back to Products List